Our Products Portfolio

Discover our comprehensive range of automation solutions designed to transform your manufacturing processes with precision, efficiency, and reliability.

Discover our comprehensive range of automation solutions designed to transform your manufacturing processes with precision, efficiency, and reliability.

Everything you need for automation

From assembly stations to specialized control systems, we provide comprehensive automation solutions tailored to your manufacturing needs.

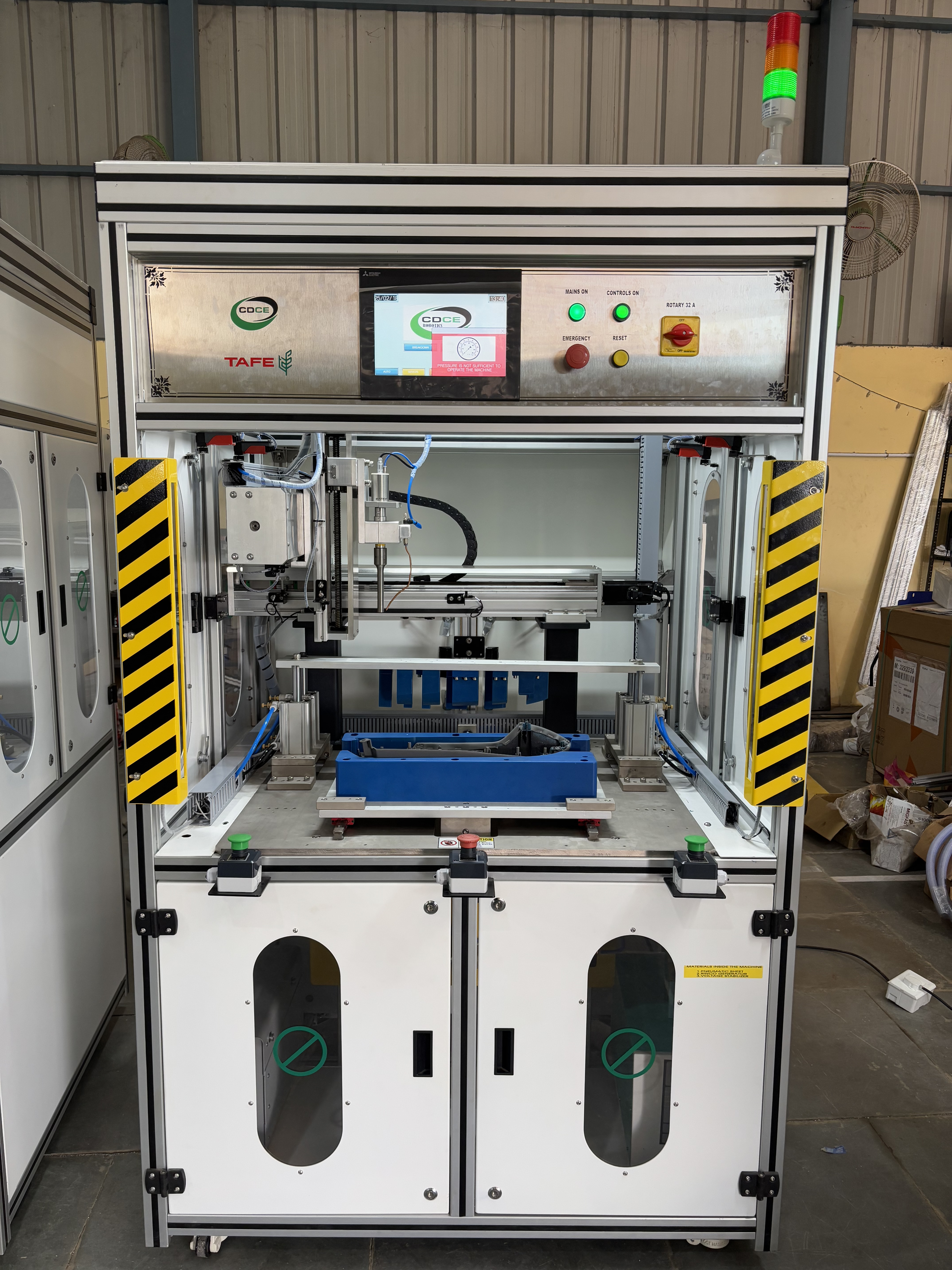

We hold the capability to design and develop the Assembly Stations as per the customized requirements of our clients. Assembly Stations are high-speed automation systems designed for industrial applications.

Our SPMs are suitable for mass production of components which involve operations like turning, boring, facing, drilling, reaming, tapping, chamfering etc, with specially designed tooling and fixture.

We are providing high quality leak testing machines developed using modern technology and in compliance with international quality standards. Our machines are highly reliable and provide accurate results.

Our vision systems provide automated inspection and quality control solutions. These systems use advanced camera technology and image processing algorithms to detect defects, measure dimensions, and ensure product quality.

Our ultrasonic welding special purpose machines provide efficient and precise welding solutions for various plastic components. These machines use high-frequency ultrasonic vibrations to create strong, reliable bonds.

Error-proofing systems that prevent defects by ensuring correct assembly and operation procedures. These systems eliminate the possibility of errors through intelligent design and automation.

Automated tracking and identification systems using barcode technology for efficient inventory management, traceability, and production control in manufacturing environments.

Custom control panels designed for automation systems with advanced monitoring and control capabilities. These panels integrate various components for comprehensive system management.

Specialized electrical panels for motor control and drive systems in industrial automation. These panels provide efficient power management and motor control solutions.

Specialized drilling machines designed for specific applications with high precision and efficiency. These machines are custom-built for repetitive drilling operations with consistent accuracy.

Advanced welding machines for hot staking applications in plastic assembly processes. These machines provide reliable thermal joining solutions for various plastic components.

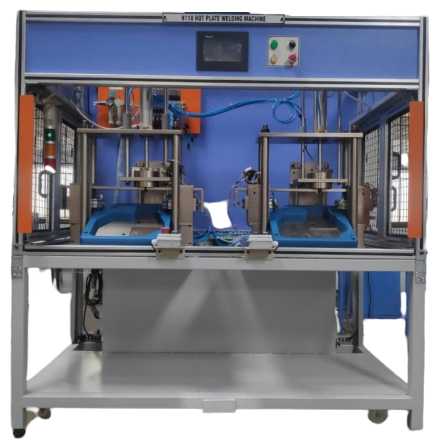

Professional hot plate welding machines for joining thermoplastic components. These machines provide uniform heating and consistent weld quality for various plastic materials.

Specialized control panels for silo and bulk material handling systems. These panels provide automated control for material flow, level monitoring, and safety interlocks.

Complete assembly line solutions designed for efficient mass production. These systems integrate multiple workstations with automated material handling and quality control.

Get in touch with our experts to discuss your automation requirements and find the perfect solution for your business needs.